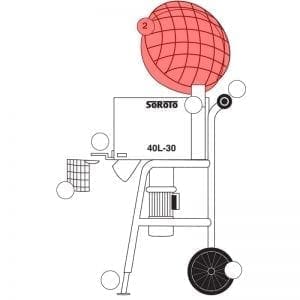

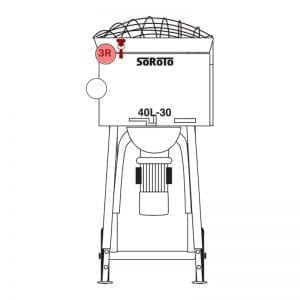

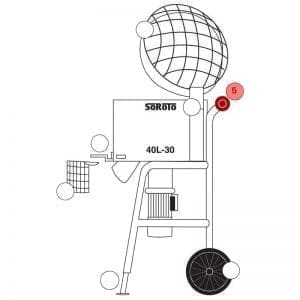

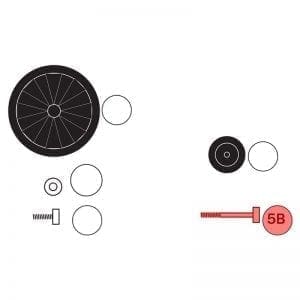

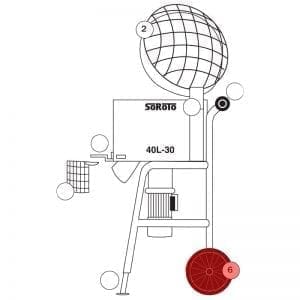

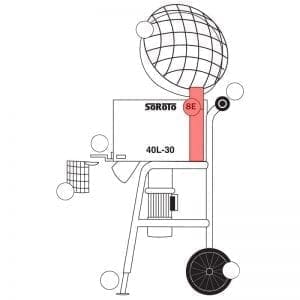

If you are looking for spare parts or replacement parts for a SoRoTo Forced Action Mixer, select the model below and you will find an exploded diagram of the mixer along with a list of parts and an enquiry form.

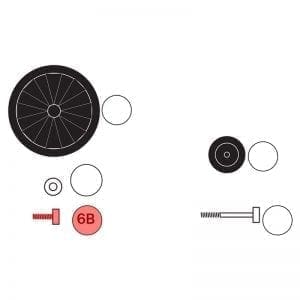

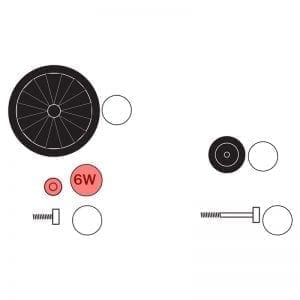

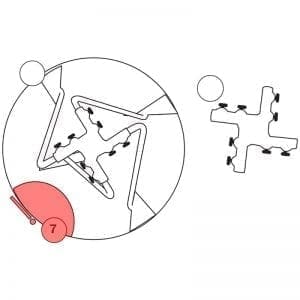

We can supply spare or replacement paddles or mixer arms for your forced action mixer, including rubber paddles for mixing materials with medium to large grade stones.