Dust controllers reduce emittance by 80%

How does a dust controller work?

Dust controllers lessen the chance of harmful materials being breathed in whilst mixing dry materials.

When dealing with materials such as cement, limestone, mortar and sand, dust is released at a large rate and dominates the space around.

If the dust is inhaled or skin or eyes are exposed, it could lead to serious long term health issues.

Watch the dust controller video

What issues can be caused by dry dust material?

There are number of issues that being exposed to dry material dust can cause.

Workers can become allergic to hexavalent chromium, which is part of cement. This allergy can last a lifetime.

The symptoms of this allergy can include mild rashes and severe skin ulcers.

If eyes are exposed to airborne dry material dust, immediate or delayed eye irritation can take place. This can range from soreness to blindness.

Inhaling large amounts of dust can develop anything from mild respiratory issues to long term illness. Varying conditions from irritated noses, wheezing, silicosis or long disease can all occur due to exposure.

How to reduce the risk of dust-triggered illnesses

There are a number of solutions recommended to avoid long-term health problems caused by exposure to dust.

Dry materials should not be used in order to reduce the amount of dangerous solutions. PPE can help to avoid it going into the body through the eyes or mouth.

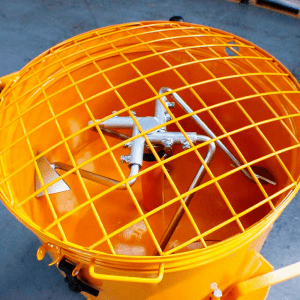

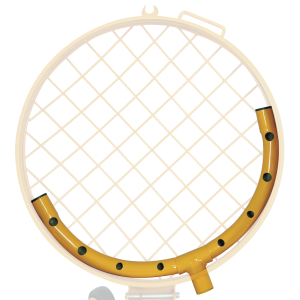

The dust controller attachment is designed to extract as much dust out of the air as possible before it has a chance to leave the mixer.

It is proven to eliminate dust emittance by 80%.

The controller minimises the amount of dust in the air without compromising access and view of the materials.

What are the advantages of the SoRoTo dust controller?

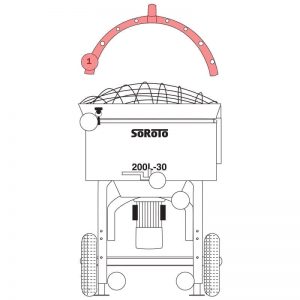

The SoRoTo dust controller can be supplied as part of a SoRoTo forced action mixer or it can be easily mounted.

The Danish Labor Inspectorate authorises its use.

It is easy to use – as it acts like a mouthpiece for the vacuum cleaner and is mounted on the mixer just under the grid lid.

The advantages include:

- The access to and view of the material is not compromised

- It dramatically reduces emittance – so there is little need for a mask for this purpose

- It is easy to mount onto both old and new mixers

- It is available on the following forced action mixer models: 80L. 100L, 120L, 200L and 300L.

- It is compatible with most industrial vacuum cleaners

How is the dust controller installed?

It is fitted onto SoRoTo forced action mixers on the inside of the grid lid.

The grid lid may have already been delivered with pre-drilled holes for the feature, which is simply screwed onto the lid.

The mixers may be fitted with the dust controller or they can be installed later on. It works on new and old models.

It is recommended that the industrial vacuum-cleaner is not connected to the plug on the mixer as it will consume power which is intended for the motor.

The controller is needed only up to the point where water is added to the mixture – but it can remain attached to the grid lid with or without the dust controller being used.

Find out more about dust controllers

The dust controller is available for all SoRoTo forced action mixers.

Browse the 300L Dust Controller

Browse the 200L Dust Controller

Browse the 120L Dust Controller

Browse the 100L Dust Controller

Browse the 80L Dust Controller

Browse the 40L Dust Controller

To find out more information call our team on 01246 418144.

Alternatively, contact us on webchat or email us here.